Like many healthcare-related practices, dentist clinics use specific equipment, chemicals, and means to tend to their customers, but this comes with health and safety risks. The Occupational Safety and Health Administration (OSHA) ensures various businesses meet the needs of workers, providing them with a safe and healthy workplace. When setting up and operating a dental office, OSHA compliance plays a key role. It mandates numerous protocols minimizing work hazards, ensuring the implementation of safety standards, proper equipment use, and more.

The Hazard Communication Standard, also known as HAZCOM or HCS, adheres to the OSHA health and safety plan. Since dental offices must comply with OSHA to continue practices and create ideal workspaces, they must also satisfy HAZCOM. Here is why dental offices follow the Hazard Communication Standard.

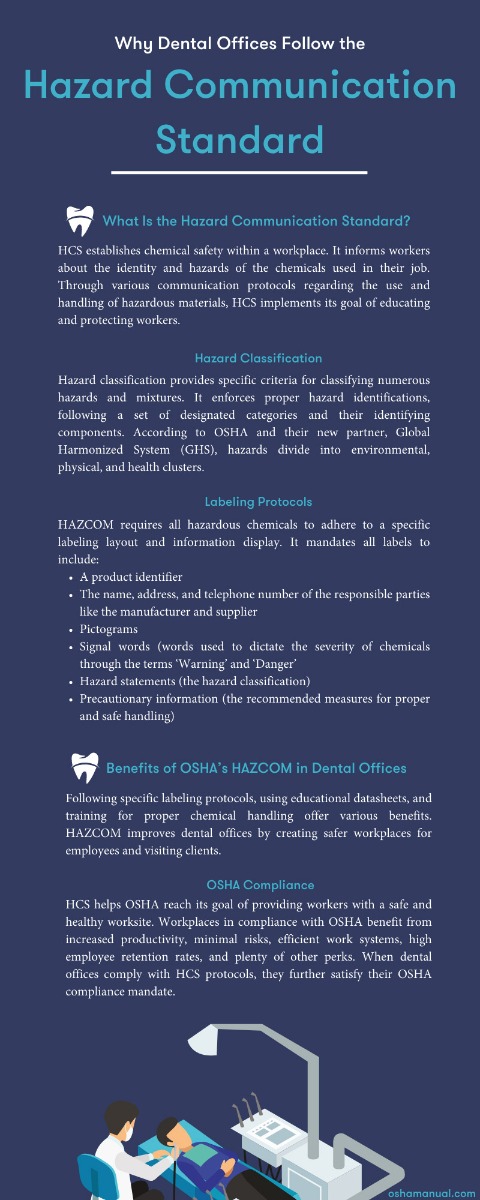

What Is the Hazard Communication Standard?

HCS establishes chemical safety within a workplace. It informs workers about the identity and hazards of the chemicals used in their job. Through various communication protocols regarding the use and handling of hazardous materials, HCS implements its goal of educating and protecting workers. Some key elements to the HCS plan include the following.

Hazard Classification

Hazard classification provides specific criteria for classifying numerous hazards and mixtures. It enforces proper hazard identifications, following a set of designated categories and their identifying components. According to OSHA and their new partner, Global Harmonized System (GHS), hazards divide into environmental, physical, and health clusters. Different notable hazards range from explosive and flammable to irritative characteristics. A lack of proper hazard classification causes potential risks of improper use and misinformation.

Labeling Protocols

HAZCOM requires all hazardous chemicals to adhere to a specific labeling layout and information display. It mandates all labels to include:

• A product identifier

• The name, address, and telephone number of the responsible parties like the manufacturer and supplier

• Pictograms

• Signal words (words used to dictate the severity of chemicals through the terms ‘Warning’ and ‘Danger’

• Hazard statements (the hazard classification)

• Precautionary information (the recommended measures for proper and safe handling)

Requiring and assigning set labels and labeling practices create universal understanding, leading to safer chemical use. Labeling protocols are often fine-tuned throughout the years, depending on new discoveries, updated technology, and added safety measurements.

Safety Data Sheets

Formally known as material safety data sheets, safety data sheets (SDSs) are chemical information files. Each chemical must come with detailed informational sheets stating:

• The chemical’s identification and product manufacturer

• The hazard identifications (matching the information listed on the labels)

• Composition and ingredients

• First-aid measures

• Firefighting measures in case the chemical starts a fire

• Accidental release measures listing recommended and appropriate responses to spills, leaks, or unintentional exposures

• Handling and storage requirements

• Exposure control

• Physical and chemical properties

• Stability and reactivity

• And toxicological information.

There are normally 18 different sections included in an SDS, with only a few that are actively mandated. Some of the additional non-mandated details included in the sheets include disposal options, transport recommendations, and regulatory information.

Information and Training

The last major protocols HCS lists are information and training standards. Whether workers come in contact with chemicals or don’t work in the same area where the chemicals are actually used, all employees must undergo training on proper labeling and information noted on their chemicals’ SDS. Educating the entire clinic’s staff coincides with OSHA’s health and safety standards, creating and preparing the entire workspace and its employees for potential hazards. Plus, achieving successful, universal, and clear communication procedures requires the majority or all party members to follow and implement the same knowledge.

Chemicals Used in Dentistry

Dentist offices use hazardous chemicals for numerous purposes spanning from anesthesia to cavity fillings and whitening solutions. Common chemicals used include nitrous oxide, mercury, silica dust, and beryllium. Since dental offices also run the risk of contracting and spreading germs, their high-grade cleaning supplies further feature hazardous chemicals. OSHA’s HAZCOM ensures that all workers in the office understand the risks and safety procedures for handling the chemicals used in their workplace.

Benefits of OSHA’s HAZCOM in Dental Offices

Following specific labeling protocols, using educational datasheets, and training for proper chemical handling offer various benefits. HAZCOM improves dental offices by creating safer workplaces for employees and visiting clients. Here are a couple of the significant benefits of having dentists comply with HCS.

OSHA Compliance

HCS helps OSHA reach its goal of providing workers with a safe and healthy worksite. Workplaces in compliance with OSHA benefit from increased productivity, minimal risks, efficient work systems, high employee retention rates, and plenty of other perks. When dental offices comply with HCS protocols, they further satisfy their OSHA compliance mandate.

Universal Understanding

HCS creates a universal understanding of chemical hazards, generating a concise form of communication across numerous boards. Clear and common forms of communication minimize potential risks, miscommunication issues, and improper handling or storing. Plus, it generates a singular, universal code and language, making it easier to educate and spread the information to numerous populations. Multiple labeling standards and informational wording increase potential risks and make learning about hazardous chemicals more challenging.

Preventative Safety Measures

The data sheets included in the HCS measures prepare workers before, during, and after handling the chemicals. Not knowing the proper response to spilled chemicals can lead to various injuries, ranging in severity. Inadequate chemical storage increases the risks of bad reactions and hazards like broken glass and spills from knocked-over chemicals, product mix-ups, and compromised solutions. And, if the chemicals are bad or compromised upon first use, the SDSs and labels under HAZCOM standards point you to the right information for legal purposes. Along with HCS’s SDSs, its other components, such as labeling procedures, training requirements, and hazard classification all help prevent and prepare dental offices for various scenarios.

In accordance with both OSHA and HCS educational philosophy and mandates, dental OSHA training includes detailed courses on how and why dental offices follow the Hazard Communication Standard. Many healthcare practices like dentistry operate in unique atmospheres, requiring specific equipment, particular legalities, niche exposure, and various interactions. Their workplaces come with additional risks which don’t occur in many other job sites. Proper training and protocols ensure that all parties within that field or in contact with dental offices remain safe, healthy, and knowledgeable.